Getting it down on paper/design

OK, so you’ve recorded your ideas and chosen one in particular. You’ve worked out something you can realistically achieve with your skills and tools and have decided on any themes and materials. Now’s the time you should be developing your idea into a concept drawing and/or a set of working drawings.All construction and engineering jobs rely on drawings and modding is no different. Whether it’s a template for a fan-hole cutout or a complex set of CAD drawings, the process of drawing out your design helps in several ways: to know whether your parts will all fit together and into your design; to give you an idea of what the finished mod will look like (and the ability to change a bad design before you mod); to provide you with accurate dimensions and templates for everything from drilling holes, to cutting out and making parts.

Drawings generally consist of one or more working drawings with dimensioned views of your parts and the whole case, and a conceptual drawing giving an idea of what the finished case will look like. Some modders may only use one, but I prefer to have both.

There are three main methods successful modders use when drawing:

- Draw it by hand: Many successful mods originated from a set of hand-drawn plans. If you consider that this was the only method available to engineers for much of human history, it’s still more than adequate today. My first mod was planned out in a series of hand-drawn sketches and they worked fine.

Hand-drawing is easy, but the main drawbacks are the inability to easily alter your drawings and the time-consuming nature of it, especially if you want an accurate and professional result. Pens, pencils a ruler and paper (preferably lined or graph-type) are all you need.

- Draw it on the computer in 2D: a faster, neater and more accurate way to draw. There are many programs available which do an excellent job. I’ve personally used Adobe Illustrator for my early 2D drawings, and found it a great tool for working out if components will fit into a design, and for creating an ‘artists impression’ of the final mod.

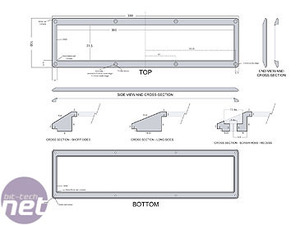

Since those days I’ve moved on to AutoCAD, which I find a lot quicker and easier (though without the ‘artistic’ features of Illustrator). AutoCAD (and most 2D CAD software) allows one to easily show dimensions of parts on the drawing and draw with great accuracy.

The advantages of using 2D CAD over hand-drawing are more than I have space to include here. One I can mention is the ability of most laser or waterjet machines to read the .dwg or .dxf (and other format) files that CAD drawings are saved in. It’s a great feeling when you can save a drawing of a part, and take the file down to the laser cutter’s to watch them simply load it in and cut it out.

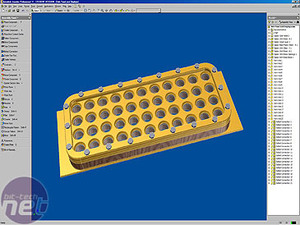

- 3D Design: The ultimate form of drawing where you combine the conceptual design of your project in 3 dimensions, with the ability to print out a set of 2D drawings. Programs range from the basic 3D conceptual/sketching like the free Google SketchUp, a favourite of modders for years, to the complex professional packages like Solidworks and Autodesk Inventor. I personally use Inventor 11 for all my 3D design work and have found I rarely touch AutoCAD now.

There is a steep learning curve involved and the professional packages are expensive, but check out the student licence options many companies offer – I run a full-featured version of Inventor on a 2-year student licence because I do a lot of design work with my engineering course and it was about 5% of the cost of buying the non-student. If you are strapped for cash, SketchUp will do the job.

From detailed drawings like the Adobe Illustrator WMD display bezel, to the simplest designs.

Professional 3D design software like Inventor takes planning to a new level and most 3D design packages offer a multitude of lighting and rendering options - the last picture is done in Autodesk Inventor.

One word of advice, however, is that whatever method you use, don’t get so caught-up in doing pretty drawings and renderings of your mod that you never get around to building it! I have seen several incredibly well-executed renderings of prospective mods hitting the forums, only to never be realised – the all too common ‘vapormod’.

Only draw what you honestly believe you can build. If you draw some incredible piece of art you’ll never be able to construct, be up-front with people that it is an exercise in design, not something you’re able to build right now, and you’ll keep the respect of your peers. Who knows, one day you may have the skills and tools to pull it off.

MSI MPG Velox 100R Chassis Review

October 14 2021 | 15:04

Want to comment? Please log in.